Alloy 825 (UNS N08825) |

|

|

|

|

|

|

|

|

|

Summary | A nickel-iron-chromium alloy with additions of molybdenum and copper. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. The alloy is especially resisitant to sulfuric and phosphoric acids. Used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment. |

|

|

|

|

|

|

|

|

Standard Product Forms | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. |

|

|

|

|

|

|

|

|

Chemical Composition Wt,% |

| Min | Max. |

| Min. | Max. |

| Min. | Max. |

Ni | 38.0 | 46.0 | Cu | 1.5 | 3.0 | C |

| 0.05 |

|

Cr | 19.5 | 23.5 | Co |

|

| Si |

| 0.5 |

|

Fe | 22.0 |

| Al |

| 0.2 | P |

|

|

|

Mo | 2.5 | 3.5 | Ti | 0.6 | 1.2 | S |

| 0.03 |

|

Nb |

|

| Mn |

| 1.0 | N |

|

|

|

Physical Constants | Density,g/ 8.14 8.14 |

|

|

|

|

|

|

|

|

Melting Range,℃ 1370-1400 |

|

|

|

|

|

|

|

|

|

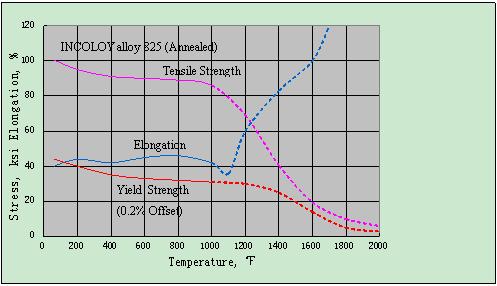

Typical Mechanical Properties | (Annealed) Tensile Strength, ksi 100 Mpa 690 Yield Strength (0.2% Offset),ksi 45 Mpa 310 Elongation, % 45 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Microstructure

Incoloy 825 has a stable face-centered-cubic structure.

Characters

Good resistance to stress-corrosion cracking;

Satisfactory resistance to pitting and crevice corrosion;

Good resistance to oxidizing and non-oxidizing hot acids;

Good mechanical properties at both room and elevated temperature, up to approximately 550℃;

Approval for pressure vessels with wall temperatures up to 450℃.

Corrosion Resistance

Alloy 825 is a versatile general engineering alloy with resistance to corrosion in acids and alkalis such as sodium or potassium hydroxide, and acidic chloride solutions. The versatility of Alloy 825 is illustrated by its use nuclear fuel element dissolvers where o variety of corrosive media, e.g. Sulphuric and nitric acids and sodium hydroxide, are handled in the same equipment.

Applications

Alloy 825 is used in a wide variety of applications up to a temperature of approximately 550℃. The typical applications are:

1. Components such as heating coils, tanks, crates, baskets and chains in sulphuric acid picking plants;

2. Sea-water-cooled heat exchangers, offshore product piping systems; tubes and components in sour gas service ;

3. Heat exchangers, evaporators, scrubbers, dip pipes etc. In phosphoric acid production;

4. Air-cooled heat exchangers in petroleum refineries;

5. Food processing;

6. Chemical plant;

7. Combustion-resistant alloy for high pressure O2 applications.