Alloy 800 (UNS N08800) |

|

|

|

|

|

|

|

|

|

Summary | A nickel-chromium alloy with good strength and excellent resistance to oxidation and carburization in high-temperature atmospheres. It also resists corrosion by many aqueous environments. The alloy maintains a stable, austenitic structure during prolonged exposure to high temperatures. Used for process piping, heat exchangers, carburizing equipment, heatingelement sheathing, and nuclear steam-generator tubing. |

|

|

|

|

|

|

|

|

Standard Product Forms | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. |

|

|

|

|

|

|

|

|

Chemical Composition Wt,% |

| Min | Max. |

| Min. | Max. |

| Min. | Max. |

Ni | 30.0 | 35.0 | Cu |

| 0.75 | C |

| 0.1 |

|

Cr | 19.0 | 23.0 | Co |

|

| Si |

| 1.0 |

|

Fe | 39.5 |

| Al | 0.15 | 0.6 | P |

|

|

|

Mo |

|

| Ti | 0.15 | 0.6 | S |

| 0.015 |

|

Nb |

|

| Mn |

| 1.5 | N |

|

|

|

Physical Constants | Density,g/ 7.94 7.94 |

|

|

|

|

|

|

|

|

Melting Range,℃ 1357-1385 |

|

|

|

|

|

|

|

|

|

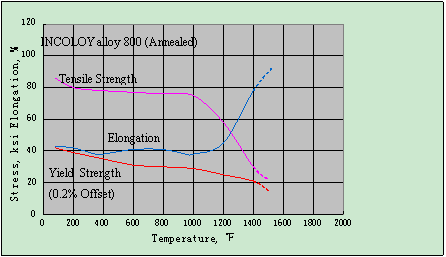

Typical Mechanical Properties | (Annealed) (1000h) Rupture Strength (1000h) ksi Mpa 1000℉/540℃ 48 360 1100℉/595℃ 32 160 1200℉/650℃ 21 50 1300℉/705℃ 11 18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|