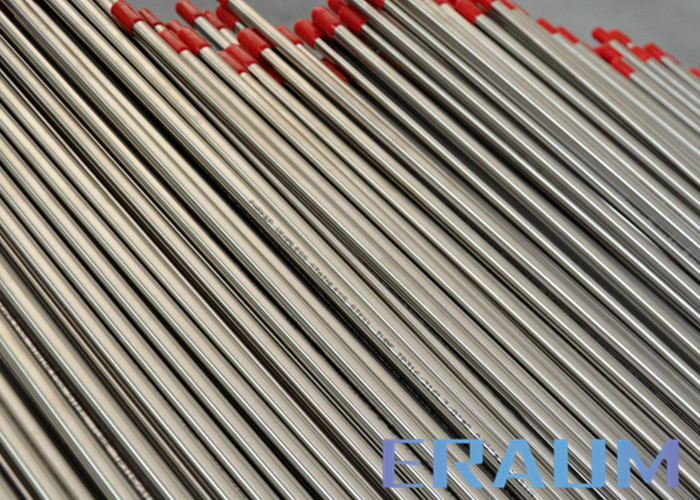

BRIGHT ANNEALED NICKEL ALLOY TUBE , ISO 9001 / PED , ANSI B36.19 ASTM B829 / ASME SB829 , ASTM B167 , ASTM B444

Email: sales@sincoteel.com vip@sincosteel.com;

SSNAT07

Price: From$45000-70000USD/TON

Material: Alloy 600, UNSN06600; Alloy 601, UNSN06601; Alloy 625, UNSN06625; Alloy 718, UNS N07718;

According to standard very strictly, nickel alloy tubes which produced by us always have correct OD and WT tolerance . Nickel alloy tubes have a very important position in thermocouple & cable industry .

Material Grade: Alloy 625/N06625, Alloy 600/ N06600,Alloy 601/N06601,Alloy 718/N07718, Alloy C276/N10276,Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc

Outer Diameter: 3.18mm-101.60mm

Wall Thickness: 0.50mm-20.00mm

Length: Normally fixed length 6m, can as per customer’s requirement

Standard: ASTM B163; ASTM B167; ASTM B444; ASTM B622 ect

Process Method: Cold Drawn or Cold Rolled

Application

a) Heat exchanger

b) Condenser

c) Shipping industry

d) Precision machinery

e) Mechanical structure industry

f) Thermocouple & Cable etc

Advantages

a) Superior surface finish

b) Better mechanical property

c) More precise dimension

d) Perfect inspection method and inspection equipment

Bright Annealed Nickel Alloy Tube , ISO 9001 / PED , ANSI B36.19 ASTM B829 / ASME SB829 , ASTM B167 , ASTM B444

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement .

According to standard very strictly, nickel alloy tubes which produced by us always have correct OD and WT tolerance . Nickel alloy tubes have a very important position in thermocouple & cable industry .

Item | Description |

Material Grade | Alloy 625/N06625, Alloy 600/ N06600,Alloy 601/N06601,Alloy 718/N07718, Alloy C276/N10276,Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc |

Outer Diameter | 3.18mm-101.60mm |

Wall Thickness | 0.50mm-20.00mm |

Length | Normally fixed length 6m, can as per customer’s requirement |

Standard | ASTM B163; ASTM B167; ASTM B444; ASTM B622 ect |

Process Method | Cold Drawn or Cold Rolled |

Application | |

| a) Heat exchanger | |

b) Condenser | |

c) Shipping industry | |

d) Precision machinery | |

e) Mechanical structure industry | |

f) Thermocouple & Cable etc | |

Advantages | |

| a) Superior surface finish | |

b) Better mechanical property | |

c) More precise dimension | |

d) Perfect inspection method and inspection equipment | |

Price Item | FOB, CFR, CIF or as negotiation |

Payment | T/T, LC or as negotiation |

Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) |

Package | Iron case; woven bag or as per customer’s requirement |

Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

Test | NTD(Ultrasonic test, Eddy Current test) |

Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test) | |

Metal Test(Metallographic Analysis, Impact Test-High/low temperature) | |

Chemical Analysis(Photoelectric Emission Spectroscopic) | |

Market | Europe, Middle East, Southeast Asia, South America. etc |

ANSI B36.19 ASTM B829 / ASME SB829 Specifications :

| NPS Designator | Outside Diameter | Nominal Wall Thickness | ||||||||

| in. | mm | Schedule 5S | Schedule 10S | Schedule 4S | Schedule 80S | |||||

| in. | mm | in. | mm | in. | mm | in. | mm | |||

| 1 / 8 | 0.405 | 10.29 | … | … | 0.049 | 1.24 | 0.068 | 1.73 | 0.095 | 2.41 |

| 1 / 4 | 0.54 | 13.72 | … | … | 0.065 | 1.65 | 0.088 | 2.24 | 0.119 | 3.02 |

| 3 / 8 | 0.675 | 17.15 | … | … | 0.065 | 1.65 | 0.091 | 2.31 | 0.126 | 3.2 |

| 1 / 2 | 0.84 | 21.34 | 0.065 | 1.65 | 0.083 | 2.11 | 0.109 | 2.77 | 0.147 | 3.73 |

| 3 / 4 | 1.05 | 26.67 | 0.065 | 1.65 | 0.083 | 2.11 | 0.113 | 2.87 | 0.154 | 3.91 |

| 1 | 1.315 | 33.4 | 0.065 | 1.65 | 0.109 | 2.77 | 0.133 | 3.38 | 0.179 | 4.55 |

| 1 1 / 4 | 1.66 | 42.16 | 0.065 | 1.65 | 0.109 | 2.77 | 0.14 | 3.56 | 0.191 | 4.85 |

| 1 1 / 2 | 1.9 | 48.26 | 0.065 | 1.65 | 0.109 | 2.77 | 0.145 | 3.68 | 0.2 | 5.08 |

| 2 | 2.375 | 60.33 | 0.065 | 1.65 | 0.109 | 2.77 | 0.154 | 3.91 | 0.218 | 5.54 |

| 2 1 / 2 | 2.875 | 73.03 | 0.083 | 2.11 | 0.12 | 3.05 | 0.203 | 5.16 | 0.276 | 7.01 |

| 3 | 3.5 | 88.9 | 0.083 | 2.11 | 0.12 | 3.05 | 0.216 | 5.49 | 0.3 | 7.62 |

| 3 1 / 2 | 4 | 101.6 | 0.083 | 2.11 | 0.12 | 3.05 | 0.226 | 5.74 | 0.318 | 8.08 |

| 4 | 4.5 | 114.3 | 0.083 | 2.11 | 0.12 | 3.05 | 0.237 | 6.02 | 0.337 | 8.56 |

| 5 | 5.563 | 141.3 | 0.109 | 2.77 | 0.134 | 3.4 | 0.258 | 6.55 | 0.375 | 9.52 |

| 6 | 6.625 | 168.28 | 0.109 | 2.77 | 0.134 | 3.4 | 0.28 | 7.11 | 0.432 | 10.97 |

| 8 | 8.625 | 219.08 | 0.109 | 2.77 | 0.148 | 3.76 | 0.322 | 8.18 | 0.5 | 12.7 |

| 10 | 10.75 | 273.05 | 0.134 | 3.4 | 0.165 | 4.19 | 0.365 | 9.27 | 0.5 | 12.7 |

| 12 | 12.75 | 323.85 | 0.156 | 3.96 | 0.18 | 4.57 | 0.375 | 9.52 | 0.5 | 12.7 |

| 14 | 14 | 355.6 | 0.156 | 3.96 | 0.188 | 4.78 | … | … | … | … |

| 16 | 16 | 406.4 | 0.165 | 4.19 | 0.188 | 4.78 | … | … | … | … |

| 18 | 18 | 457.2 | 0.165 | 4.19 | 0.188 | 4.78 | … | … | … | … |

| 20 | 20 | 508 | 0.188 | 4.78 | 0.218 | 5.54 | … | … | … | … |

| 22 | 22 | 558.8 | 0.188 | 4.78 | 0.218 | 5.54 | … | … | … | … |

| 24 | 24 | 609.6 | 0.218 | 5.54 | 0.25 | 6.35 | … | … | … | … |

| 30 | 30 | 762 | 0.25 | 6.35 | 0.312 | 7.92 | … | … | … | … |

- ASTM A312 TP304 / 304L STAINLESS STEEL ANNEALED & PICKLED SEAMLESS INDUSTRIAL PIPE

- ASTM A312 / ASME SA312 TP309S / 310S INDUSTRIAL PIPE FOR CHEMICAL INDUSTRY

- 10BWG DN200 STAINLESS STEEL SEAMLESS / WELDED PIPE WITH COLD ROLLED

- 18INCH STAINLESS STEEL SEAMLESS PIPE WITH PICKLED SURFACE

- 28INCH 18SWG BIG SIZE STAINLESS STEEL INDUSTRIAL PIPE FOR TRANSPORTATION

- 1.4306 / 1.4404 ANNEALED & PICKLED STAINLESS STEEL SEAMLESS PIPE FOR INDUSTRY

- Stainless steel seamless steel pipe

- 304 316 Stainless steel seamless steel pipe

- 1.4301 1.4307 Stainless steel seamless steel pipe

- 1.4307 AP Stainless steel seamless steel pipe

- 1.4404 Stainless steel seamless steel pipe

- tp321 Stainless steel seamless steel pipe

- TP304 Stainless steel seamless steel pipe

- SANITARY POLISH TUBE

- TP304 Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- Stainless steel seamless steel pipe

- MULTI-CORE CONTROL LINE 1/2INCH 316L WITH PVDF ENCAPSULATION FOR OIL & GAS

- SHEATHED MULTICORE TUBING & SINGLE CORE TUBING

- ASTM A213 TP304L 1/4 INCH BRIGHT ANNEALED INSTRUMENT COILED TUBE

- ASTM A213 TP304 9.53MM COILED TUBING MANUFACTURER

- ASTM A269 WELDED CAPILLARY TUBE SS TP316L DOWNHLE TUBE FOR OILFIELD SERVICES

- DDV CONTROL LINE ALLOY 825 STAINLESS STEEL WELDED COILED TUBING FOR CHEMICAL INJECTION LINE

- S31803 / 2205 DUPLEX STEEL TUBE WITH PICKLING SURFACE FOR OIL REFINERY

- 1.4462 / 1.4410 COLD ROLLED DUPLEX STEEL WELDED TUBE, ASTM A789 / ASME SA789

- DUPLEX STEEL TUBE

- SAF2507 / 1.4410 DUPLEX STEEL TUBE, 1 / 2 INCH 12SWG FOR PIPELINES

- F51 / F53 SMALL DIAMETER DUPLEX STEEL TUBE, ASTM A789 / A790 COLD ROLLED TUBE

- 31803. 32750Stainless steel seamless steel pipe

- A928 2205 duplex steel Stainless steel seamless steel pipe

- 32760/32750 Stainless steel seamless steel pipe

- 2205 Stainless steel seamless steel pipe

- ASTM B619 / ASME SB619 ALLOY C276 NICKEL ALLOY WELDED PIPE

- ASTM B619 ALLOY S / UNS N06635 NICKEL ALLOY WELDED PIPE

- ASTM B619 / B626 ALLOY 230 / UNS N06230 NICKEL ALLOY WELDED PIPE

- ALLOY C22 / UNS N06022 NICKEL ALLOY SEAMLESS PIPE FOR CHEMICAL INDUSTRY

- ASTM B622 / B619 ALLOY G-30 / UNS N06030 NICKEL ALLOY PIPE

- ASTM B407 / B829 INC 800 / 800H / 800HT NICKEL ALLOY SEAMLESS PIPE

- ASTM A564 / ASME SA564 ALLOY G-35 / UNS N06035 NICKEL ALLOY WELDED NECK FLANGE

- NICKEL ALLOY C276/UNS N10276 HEAT EXCHANGE COLD ROLLED TUBE FOR PRESSURE VESSEL

- NICKEL ALLOY 625/825 HEAT EXCHANGER TUBE BA/AP SURFACE FOR CHEMICAL EQUIPMENT

- UNS N10276 NICKEL ALLOY SEAMLESS PIPE / TUBE, ASTM B619 / ASME SB619

- ASTM B163 / B423 ASME SB163 / SB423 ALLOY 825 NICKEL ALLOY SEAMLESS TUBE

- ASTM B167 / B829 ALLOY 617 / UNS N06617 NICKEL ALLOY SEAMLESS TUBE

- BRIGHT ANNEALED NICKEL ALLOY TUBE , ISO 9001 / PED , ANSI B36.19 ASTM B829 / ASME SB829 , ASTM B167 , ASTM B444

- Butt welding pipe fitting

- ASTM A351 1/8” CF8 / CF8M THREAD CAP CASTING FITTING

- THREADED HEX PLUG THREADED COUPLING THREADED ELBOW

- FORGED STEEL PIPE FITTING HIGH PRESSURE RATING FITTING

- 304 / 316 STAINLESS STEEL FLANGES PIPE FITTINGS , WN/ SO/PL/BL FLANGE

- ASME B16.5 FLANGES PIPE FITTINGS , BLIND 150LB RF

- F316L / 316 STAINLESS STEEL FLANGE , PLRF ASTM A182 PN16 DN150 FLANGE

- F304 STAINLESS STEEL FLANGE FOR CONNECTION , WNRF SCH80 A / SA182 150 CLASS

- ASTM A182 F304 / 304L 150-2500LB STAINLESS STEEL BLIND FLANGE FF

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

- Flange

Chinese

Chinese English

English Spanish

Spanish Russian

Russian